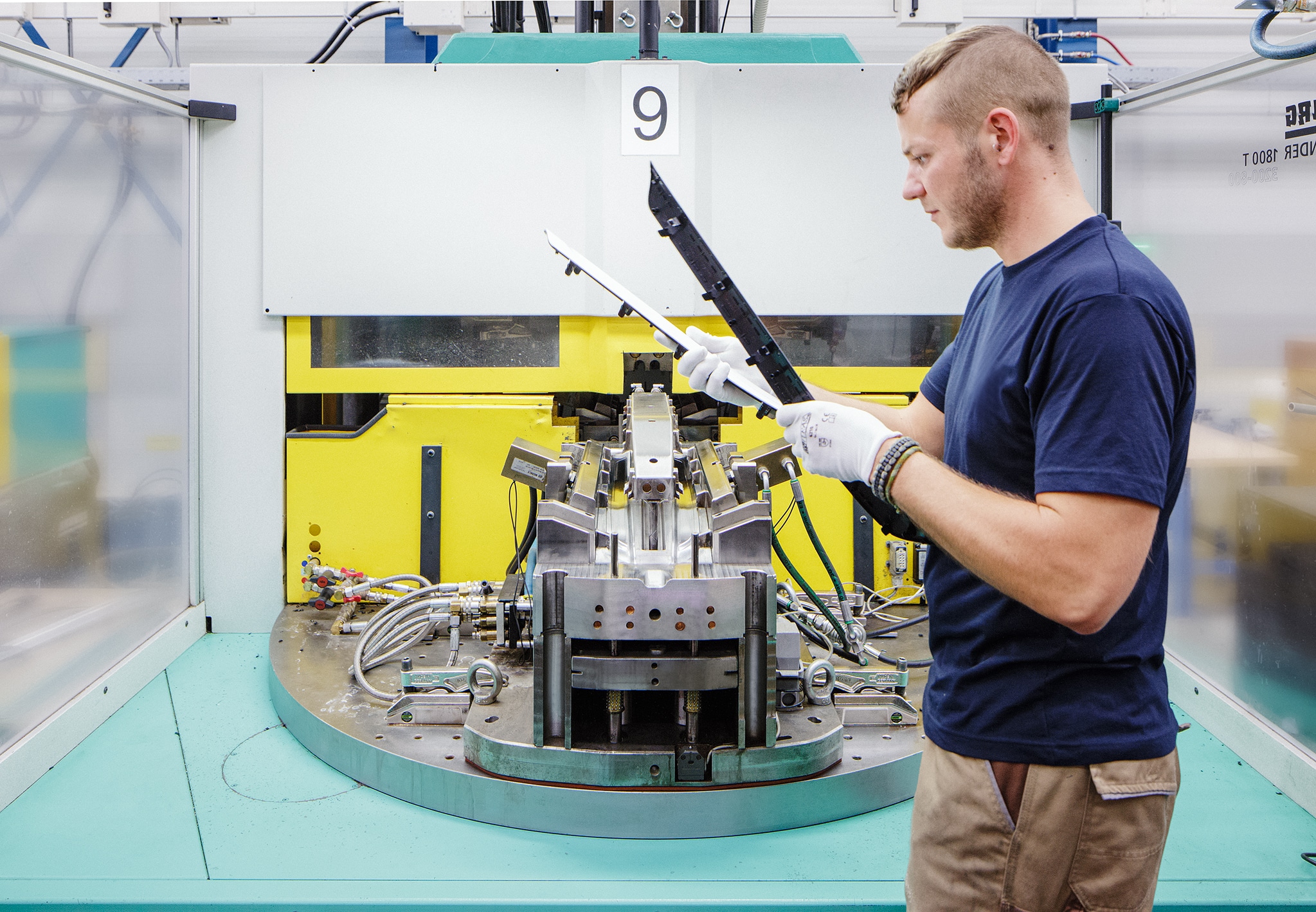

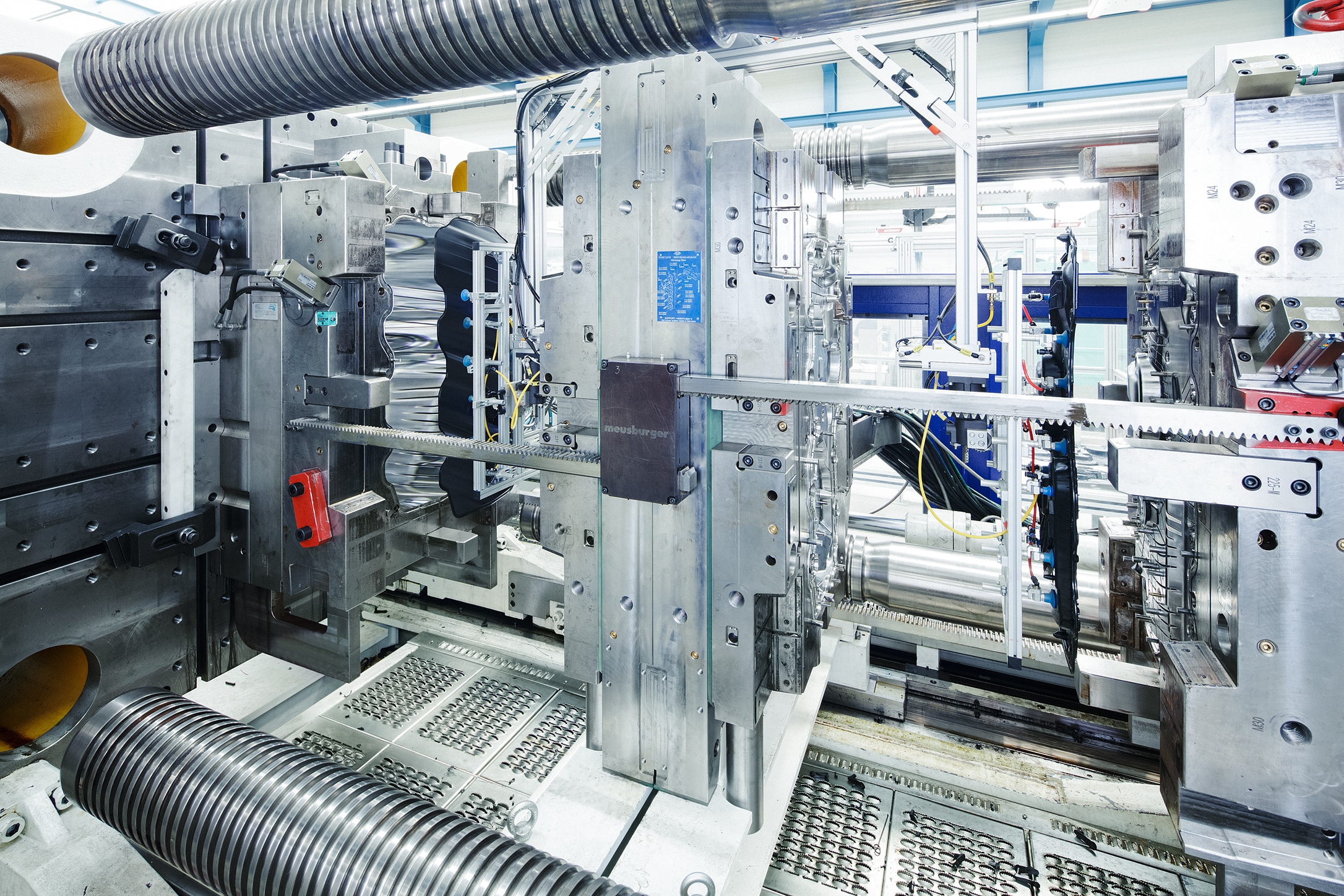

TOOLMAKING – THE SKILLED TRADE WE HAVE LEARNED.

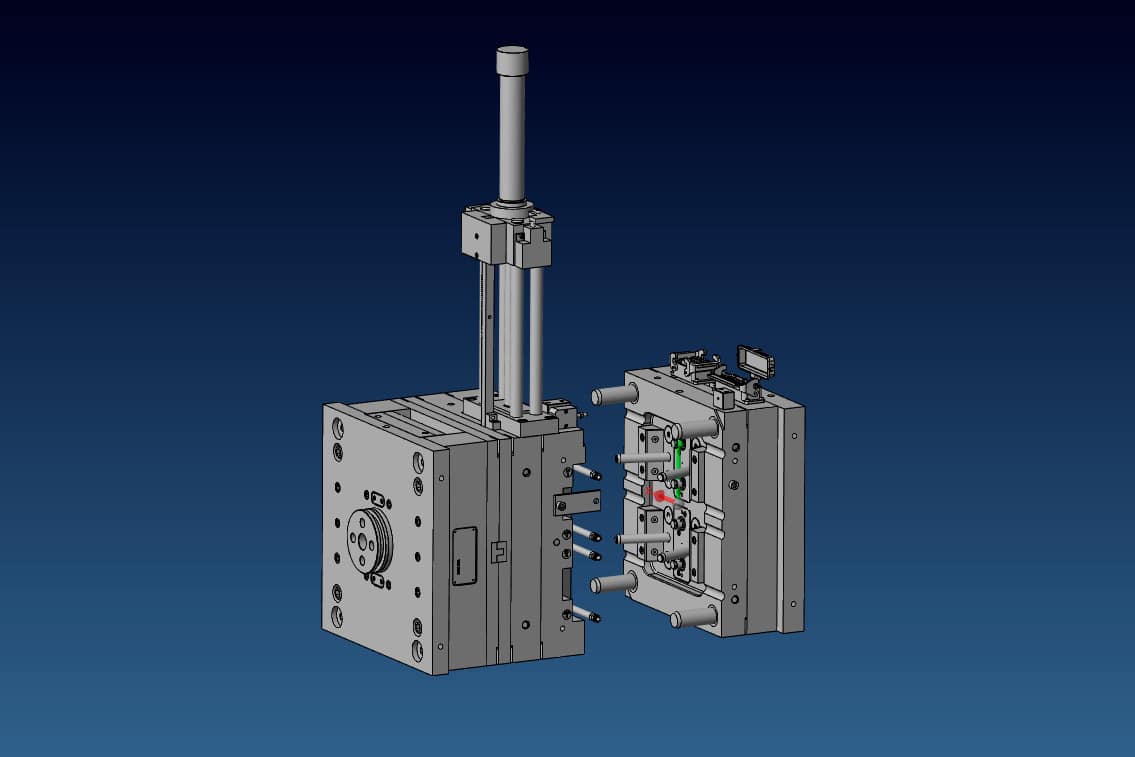

With rigorous planning, perfect project management and dependable partners we are able to deliver a wide range of different tools quickly and to the highest quality. For every requirement – for every market. Even when our network partners are involved in the construction, the tools are still completed, tested, run in and sampled in Lindberg, and the quality of the manufacturing is tested here as well at the right time.

OUR SERVICES

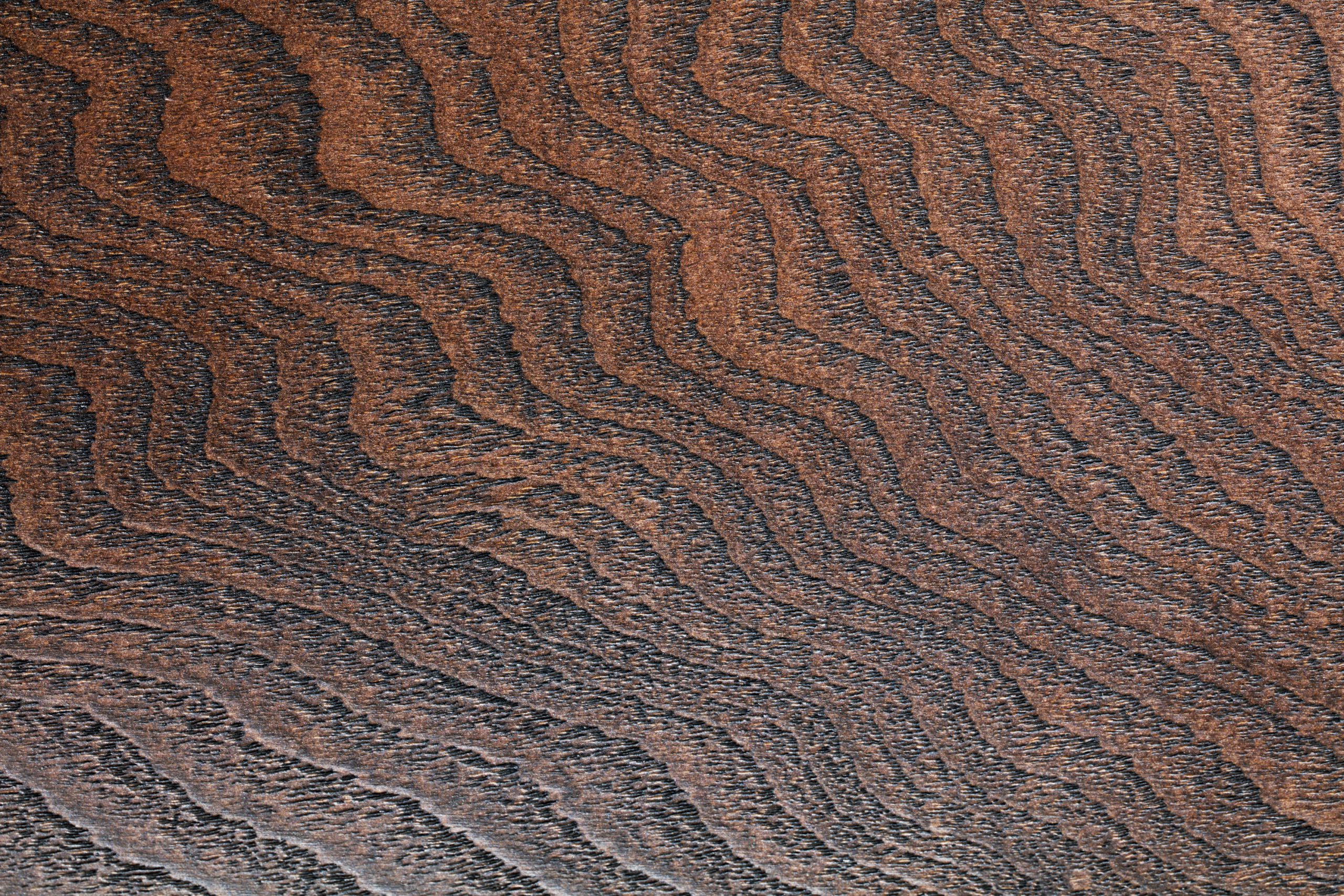

Back injection moulding tools

Injection moulding tools

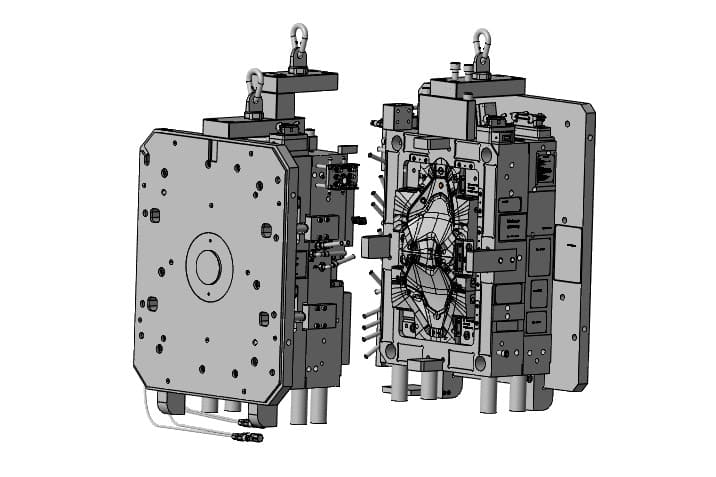

Stack moulds

Two-component tools

Stamping and forming tools

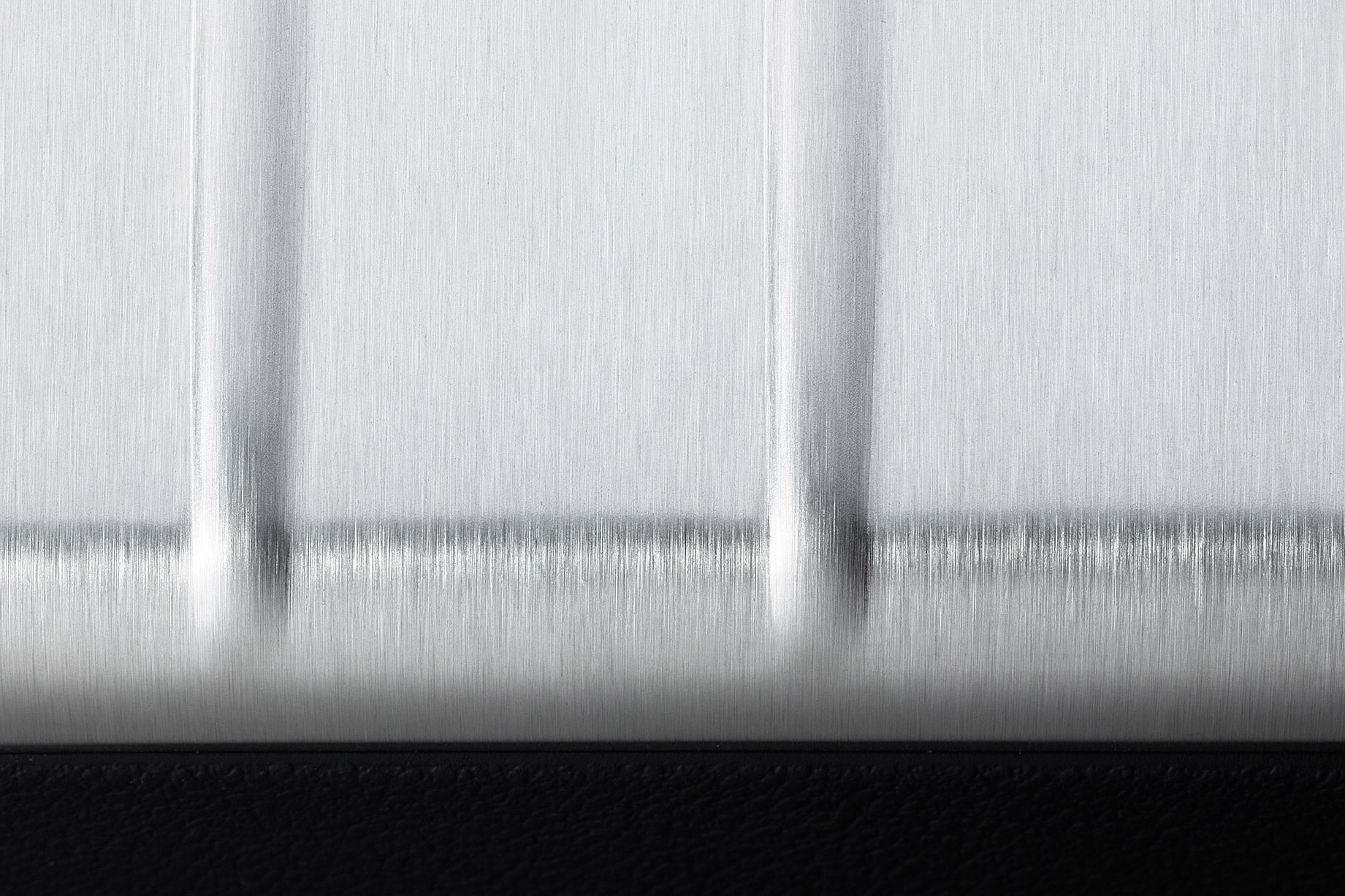

Variotherm tools

Injection moulds with variothermal temperature control can be used for plastic parts that require a high quality surface finish and minimal warpage. It can also be used for levelling visible weld seams. We will be happy to discuss any special requirements you may have in order to develop a series solution.

GIT/WIT

Fluid-assisted injection moulding methods are primarily used for manufacturing injection moulded parts with cavities. In recent years, we have gained valuable practical experience in the manufacturing of tools using gas injection and water injection technology.