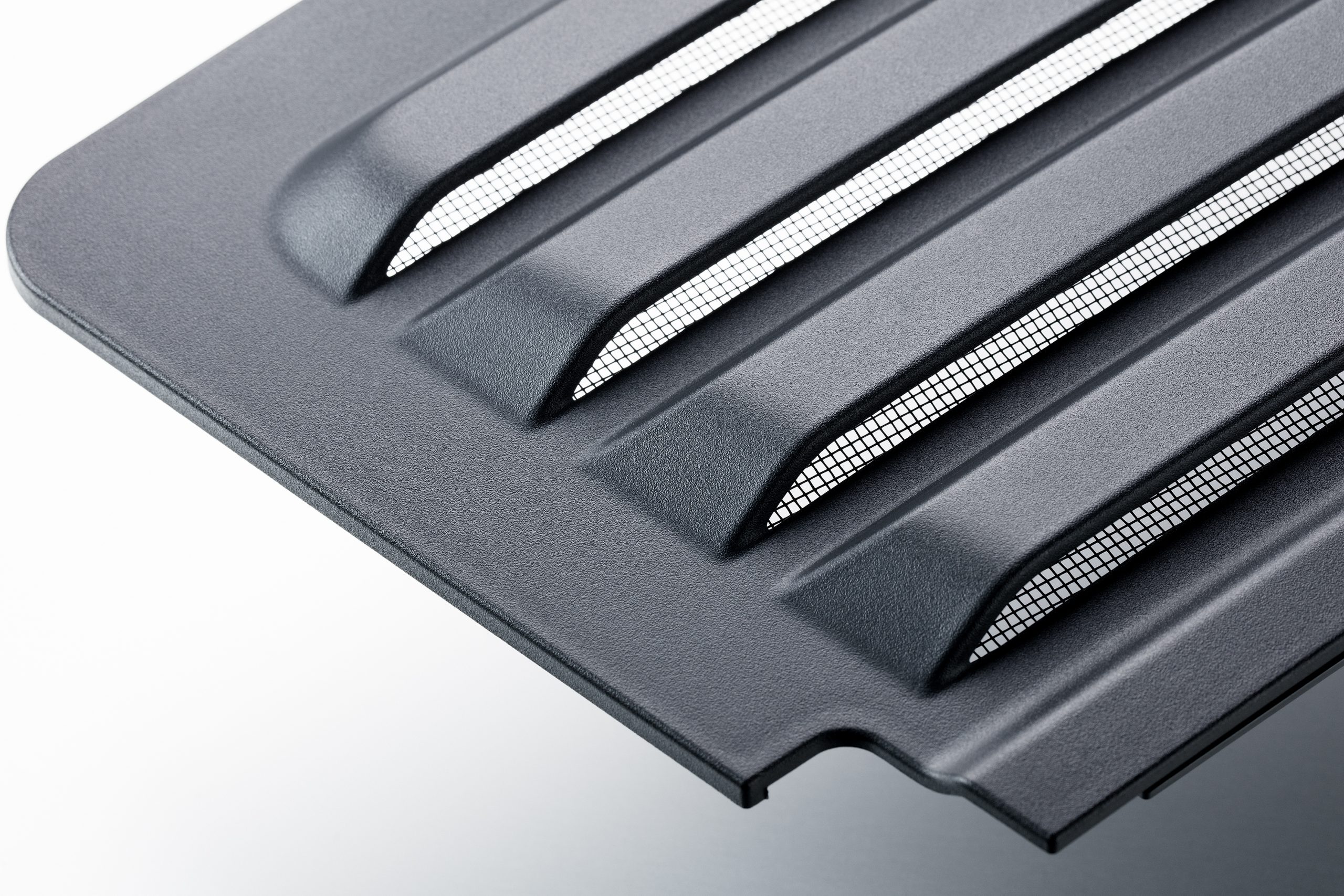

The Erbiwa Tech brings its design perfectly to the series.

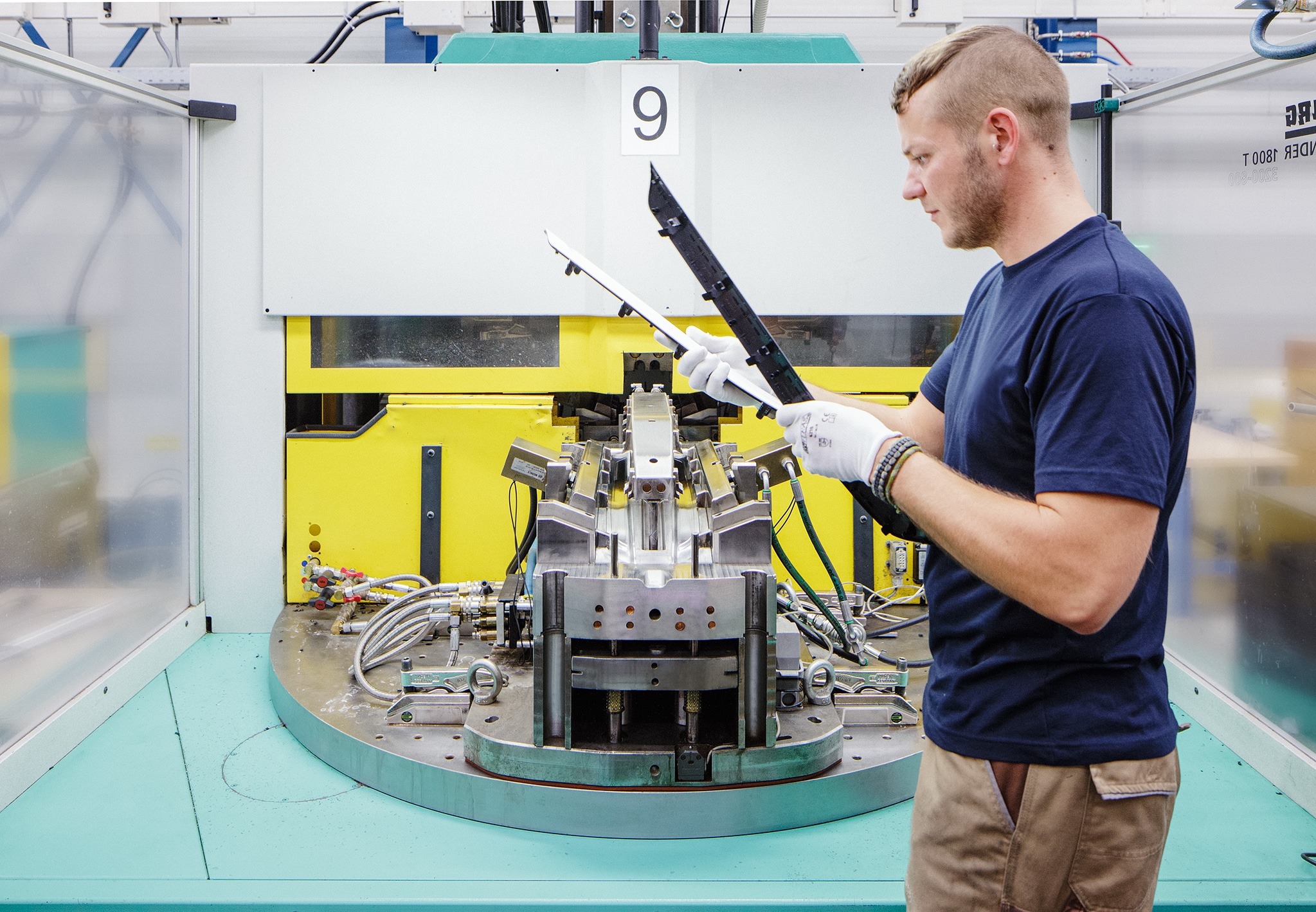

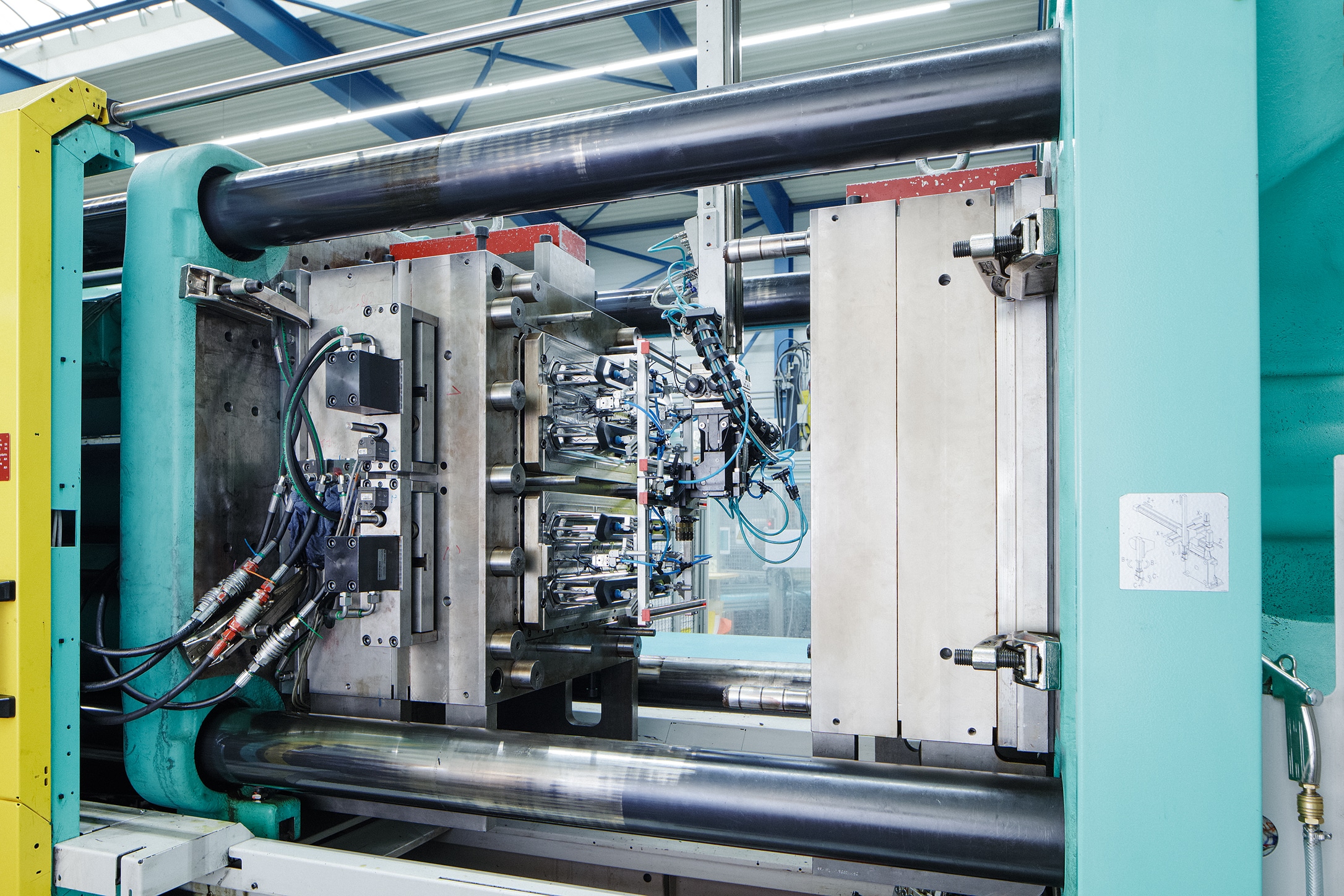

At ERBIWA tech GmbH we undertake to deliver your plastic part to series production. Perfectly. In addition to the 1,300t machine, a machine with a clamping force of 1,600t is also available.

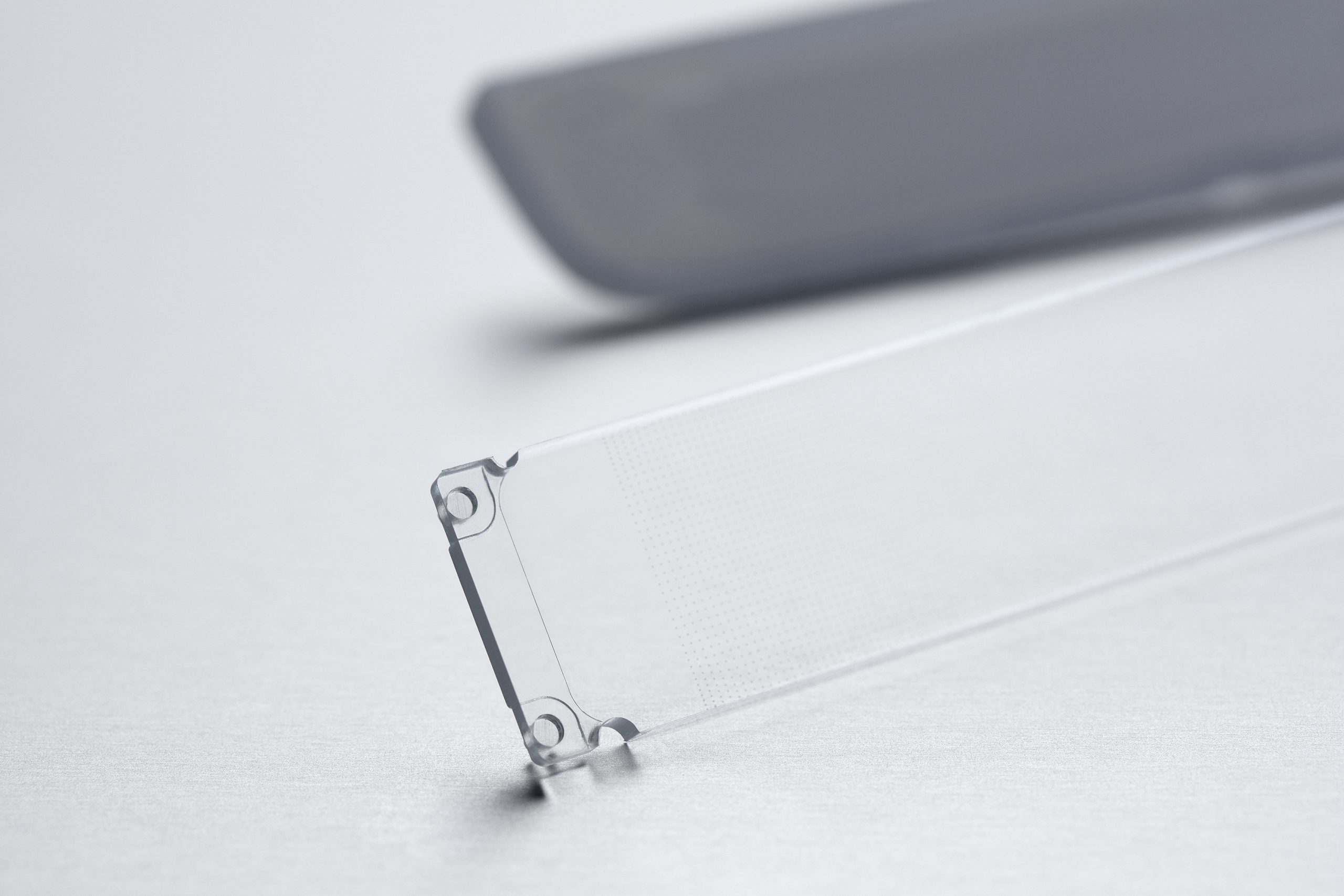

The design, engineering, simulation and toolmaking all take place in-house, so we can guarantee perfection down to the smallest detail.

so we can guarantee perfection down to the smallest detail. Again you can decide for yourself whether to opt for the entire process to be supported by our team, or whether to limit that support to individual areas.

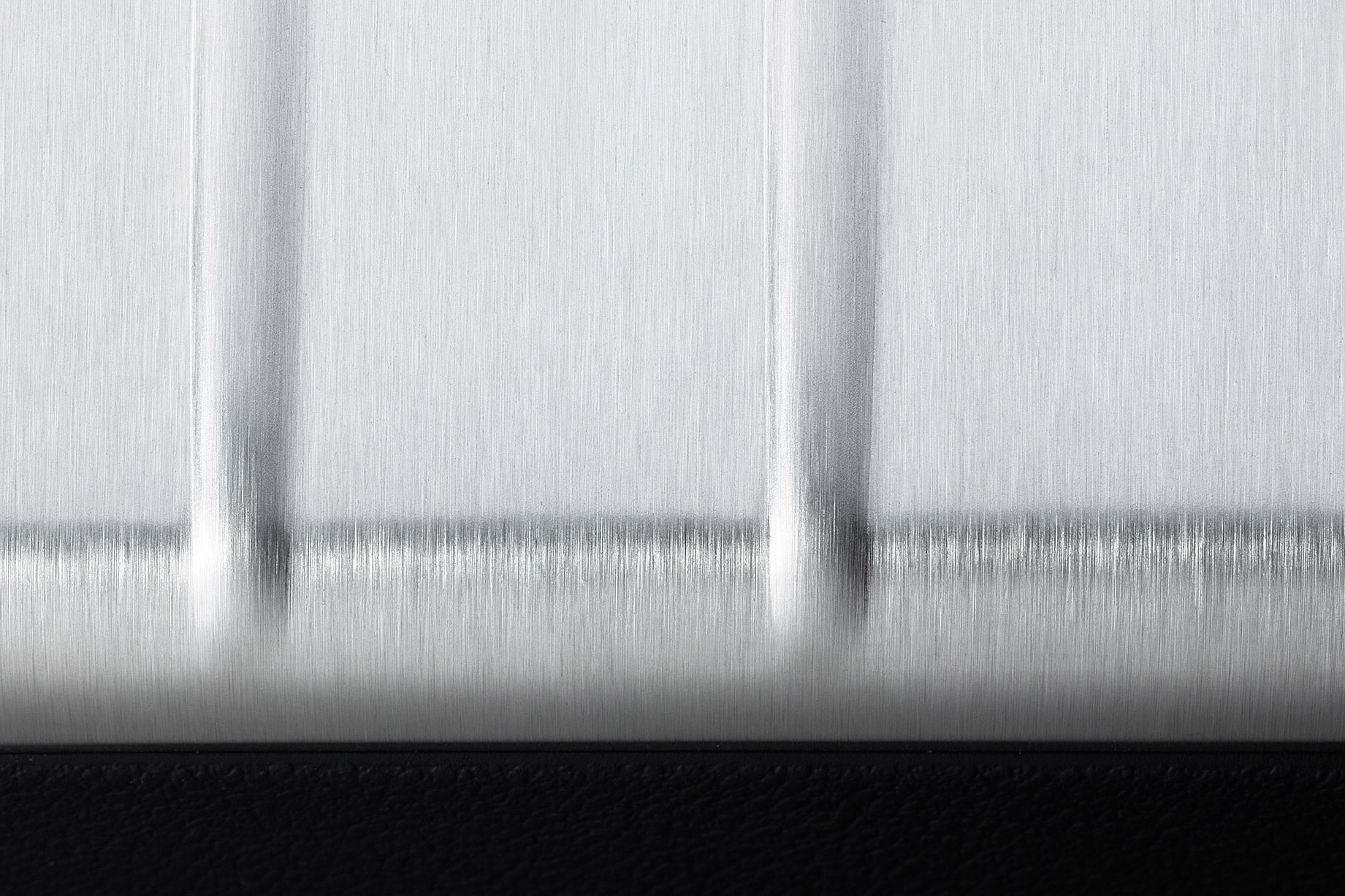

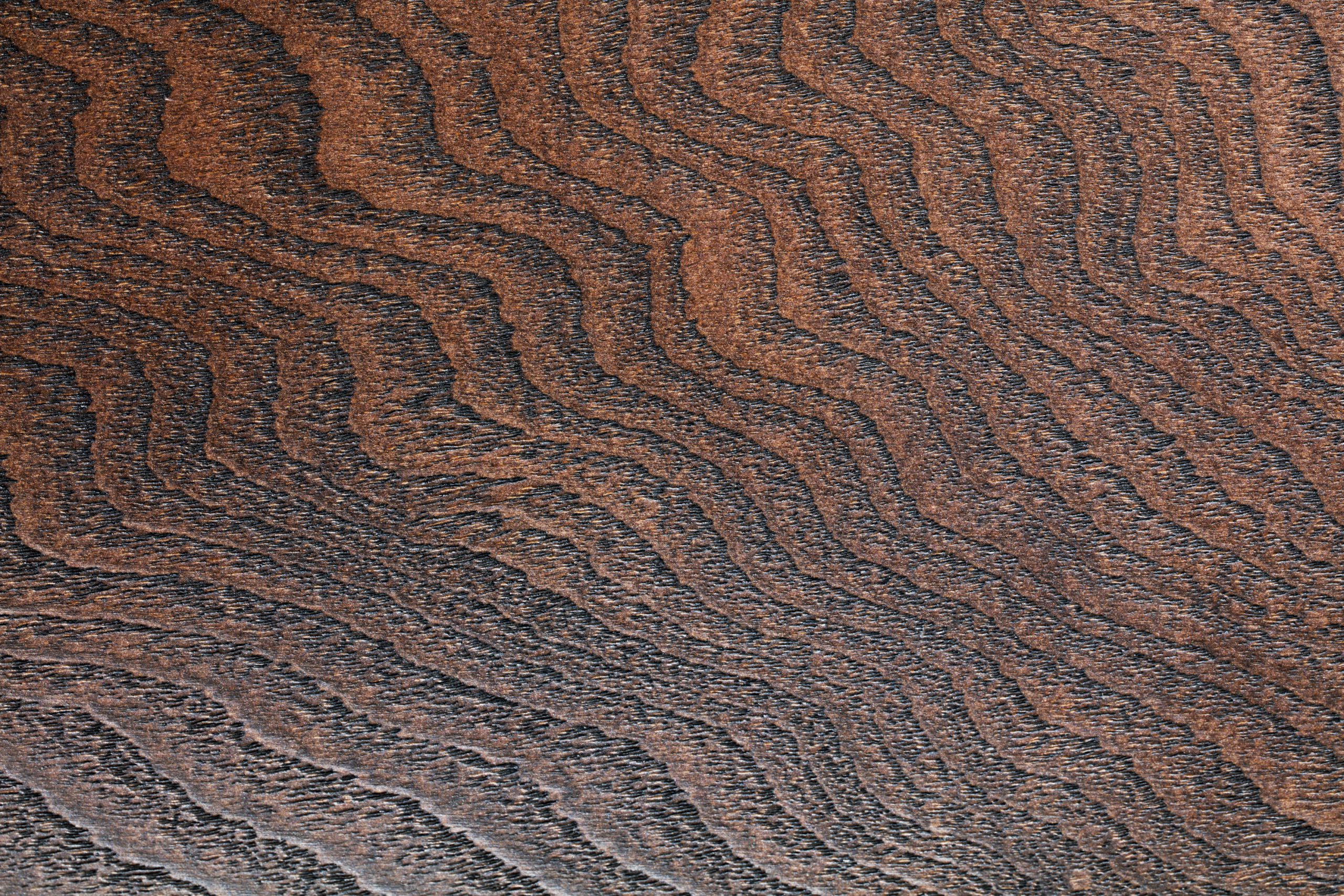

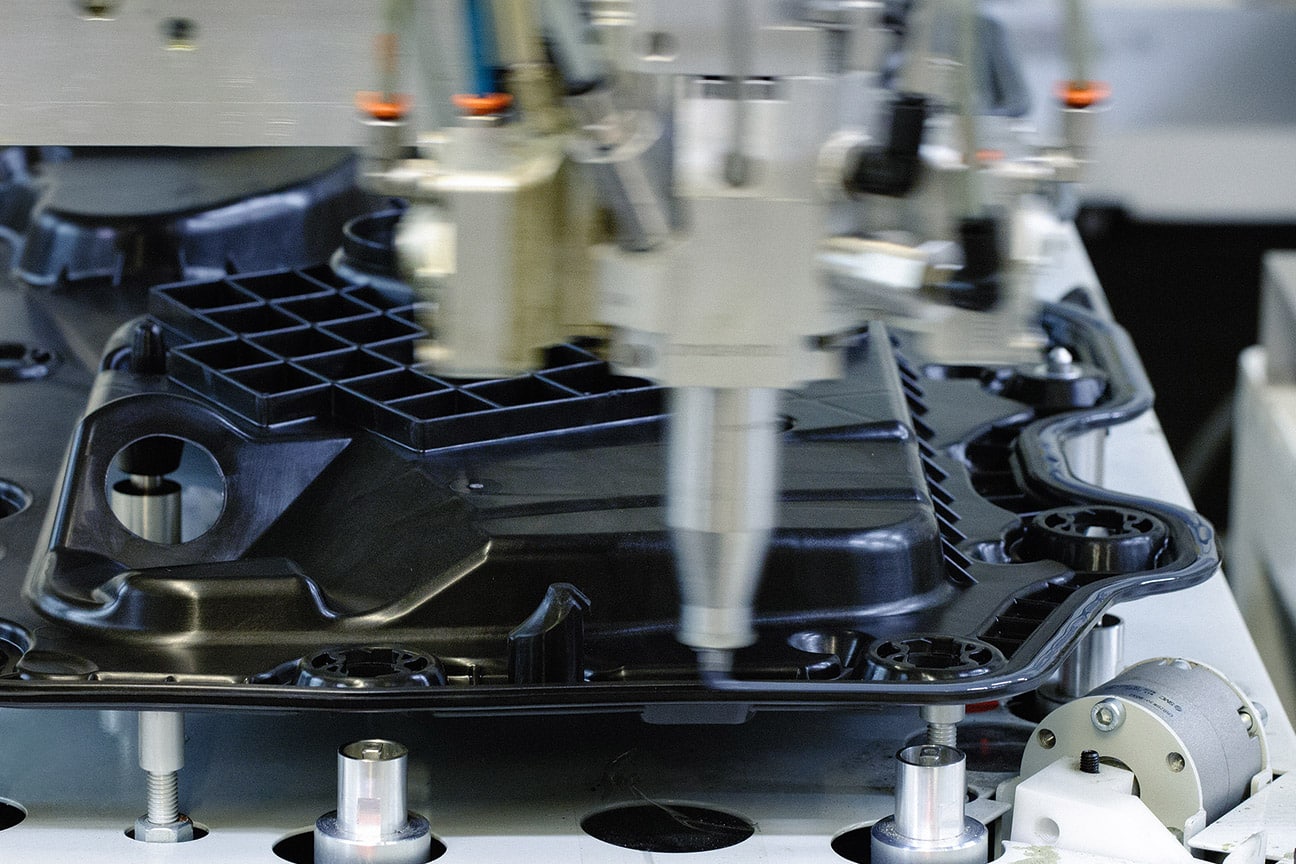

We can draw upon many years’ experience of the back-moulding of aluminium casings and wood applications. Subsequent finishing processes such as the application of PUR foam sealing beads or paint finishes are often included.

OUR SERVICES

light systems

ERBIWA tech GmbH is IATF 16949-certified.