PILOT PLANT THROUGH TO SERIES PRODUCTION

OUR SERVICES

Tool test bench

Upon completion of new tools and after modifications to existing tools or maintenance we can put our injection moulding tools through their paces and run them in using the run-in station we developed in-house. Whether installed vertically or horizontally, with ejector rod or hydraulic ejector assembly, the first few thousand cycles are tested under individual temperature control conditions which allows us to carry out a quality check on the tool even before the initial sampling at the injection moulding machine.

This fixed component of the tool creation process is an important step that enables us to guarantee certainty and calm in the project workflow.

Sampling

Service is the key to our success: sampling included! We have a sampling machine park in the clamping force range from 50 to 1,600 tons. This means that we can automate the running in of your products using handling equipment, if necessary, and bring them to series production. If you want to carry out extended parameter or material tests, you will naturally be welcome to come to our pilot plant.

Testing instruments

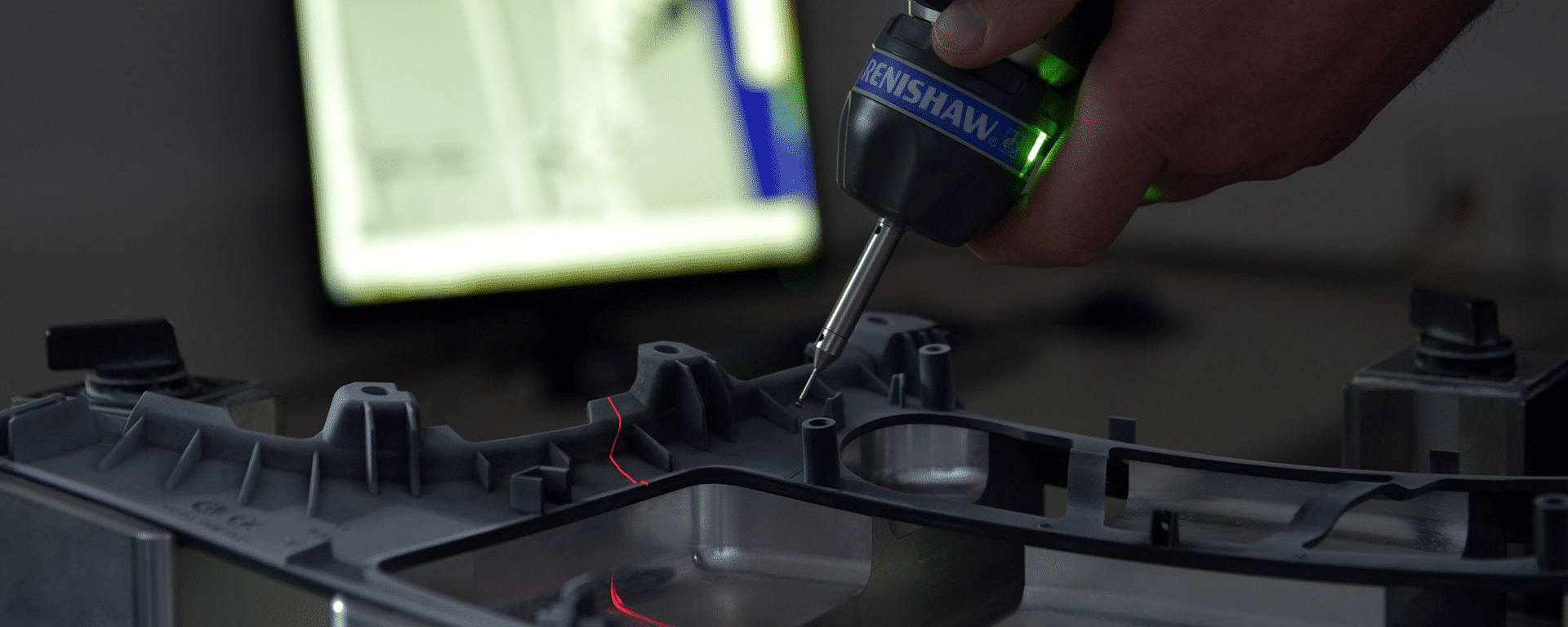

We accept no compromises with respect to quality assurance in toolmaking.

Component tests have top priority for us. We use the latest technology to monitor and optimise all our products and production processes. These include a FARO 3D arm scanner with tactile or non-contact functions that allow us to non-destructively measure and image even the tiniest deviations from the desired product specification.

Possible geometric deviations in the first off-tool parts are fed back to the simulation department if necessary, where optimised solutions are drawn up in further calculation loops before modifications are made to the tool. This reduces the cost of reworking.

Thermal imaging measurements are also used where necessary. For example, it is possible to identify the hotter regions of a plastic part or the tool in order to fine-tune the cooling system. This enables us to meet both your and our requirements with consistently high quality.

Small batch and pre-series

Do you need small batch or pre-series production? Then you have come to the right place. It is in our own interest to go one step further with your new tool. With our in-house pilot plant this is a straight-forward process that can be quickly implemented. So through us you can access additional capacity (human and machine) taking you into the production phase at the right time – relaxed and with certainty.